Our Services

Lensee Automation specializes in delivering highly customized AI vision inspection equipment and automation solutions for the industrial manufacturing sector. With deep industry expertise and technological know-how, we are committed to fusing artificial intelligence with automation to help manufacturers achieve efficient production and intelligent quality control.

We provide the following services and solutions:

- Non-standard Customized Equipment & Solutions

We have a deep understanding of various industries’ processes and product requirements. Based on actual factory needs, we design and deliver non-standard tailor-made vision inspection equipment and automated production lines, providing comprehensive customization from hardware to software.

- Customizable Software Platforms

We offer three proprietary software products: an AI deep learning tagging & training app and a zero-code/low-code vision platform app, as well as a defect verification app. All of these applications can be tailored on multiple levels—features, interface, algorithms—to match the customer’s inspection requirements, process flows, and on-site systems, ensuring flexible adaptation to diverse industrial scenarios.

- End-to-End Turnkey Service

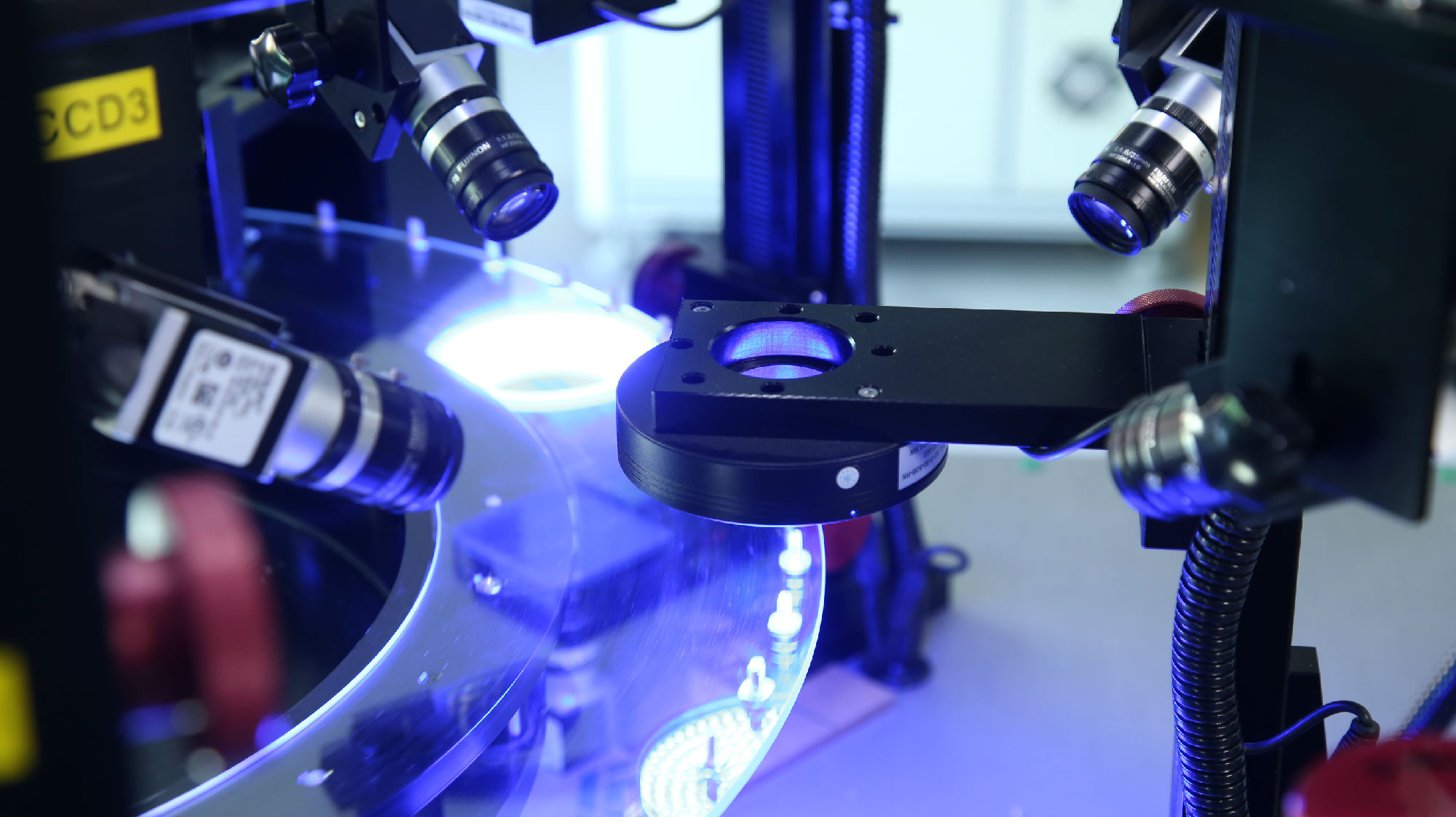

Our professional engineering team consists of mechanical, electrical, optical, software and AI algorithm engineers. From requirement analysis, customized solution design, equipment manufacturing, software and algorithm development, on-site integration to ongoing maintenance, we provide a one-stop turnkey experience for our clients.

- Continuous Optimization & Responsive Support

Equipped with a large assembly and testing workshop, we have robust delivery and equipment upgrade capabilities. We continuously refine our systems based on actual site conditions, ensuring every solution stays aligned with our clients’ evolving business needs.

Industry Applications

- Consumer Electronics: Customized surface inspection for phone housings and structural parts

- Automotive Components: Multi-type stamping, casting, and plastic part defect detection

- Medical Devices: High-precision, customized appearance and packaging inspection

- Semiconductors: Wafer, chip, and component appearance and dimension inspection

- PCB (Printed Circuit Boards): Solder joint, circuit, and surface defect inspection

- Display Panels: Automated inspection for LCD, OLED, and other display modules

- Photovoltaics: Inspection for solar cells, PV modules, and related components

- New Energy: Inspection for lithium batteries and other emerging energy products

- Hardware & Machining: Dedicated inspection equipment for screws, bearings, and other mass-production parts

Service Regions

While Lensee Automation has a solid foundation in domestic market, we are actively expanding our international business. We have already established cooperation or initiated projects with manufacturers in Vietnam, Malaysia, Singapore, Japan, Korea, and several countries in Europe and North America. We are committed to providing professional, customized AI vision inspection and automation solutions for overseas clients, and are steadily building robust international project management and remote technical support systems to deliver efficient, reliable smart manufacturing services globally.

Cooperation Process

- Personalized requirement communication and on-site survey

- Product sample testing

- Customized solution design and technical review (DFM)

- Equipment manufacturing, software customization, AI algorithm development

- On-site installation, commissioning, and acceptance

- Training, delivery, and ongoing support

R&D Strength

Lensee Automation has a multidisciplinary R&D team covering AI, machine vision, automation, optics, and software development. We continuously invest in core technology, with strong capabilities in developing proprietary AI algorithms, software and hardware platforms, and non-standard solutions. Equipped with advanced R&D labs and in cooperation with top universities and research institutes, we ensure continuous innovation and technical leadership, enabling rapid response to customer-specific needs.

Software and Algorithm

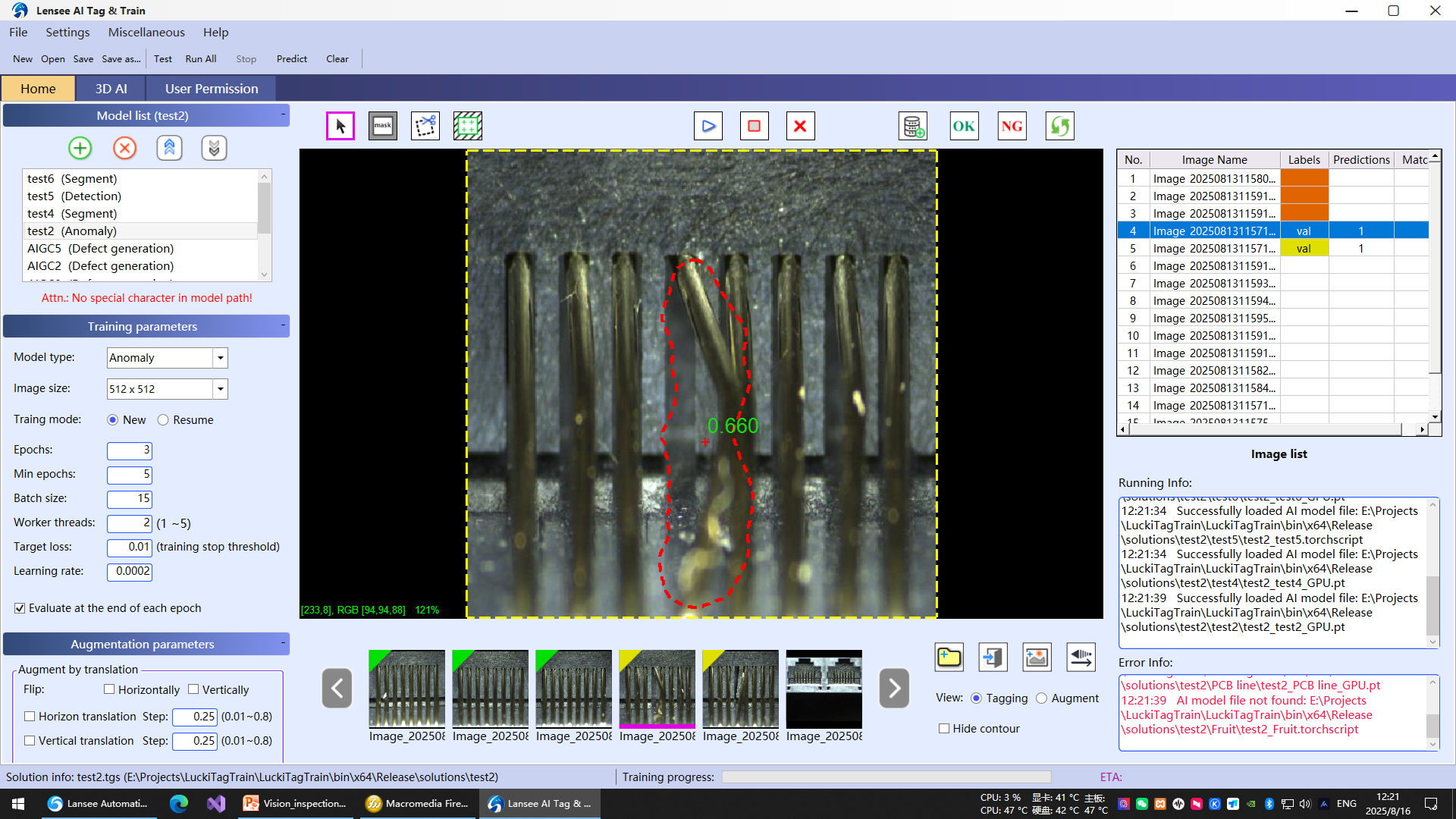

1. Our AI app: AI plays a crucial role in smart manufacturing (Industry 4.0). Our team has developed a proprietary AI platform specifically designed for industrial defect detection. Powered by an intuitive view of augmented images, this software supports few-shot tagging and training for mainstream models, including object detection, segmentation, classifier, anomaly detection, and AIGC-driven defect generation—significantly enhancing vision capabilities in smart manufacturing. With our app, users need only 3 to 8 training images to create an accurate model for defect and anomaly detection, minimizing false positives. The entire tagging and training process can be completed in just a few minutes.

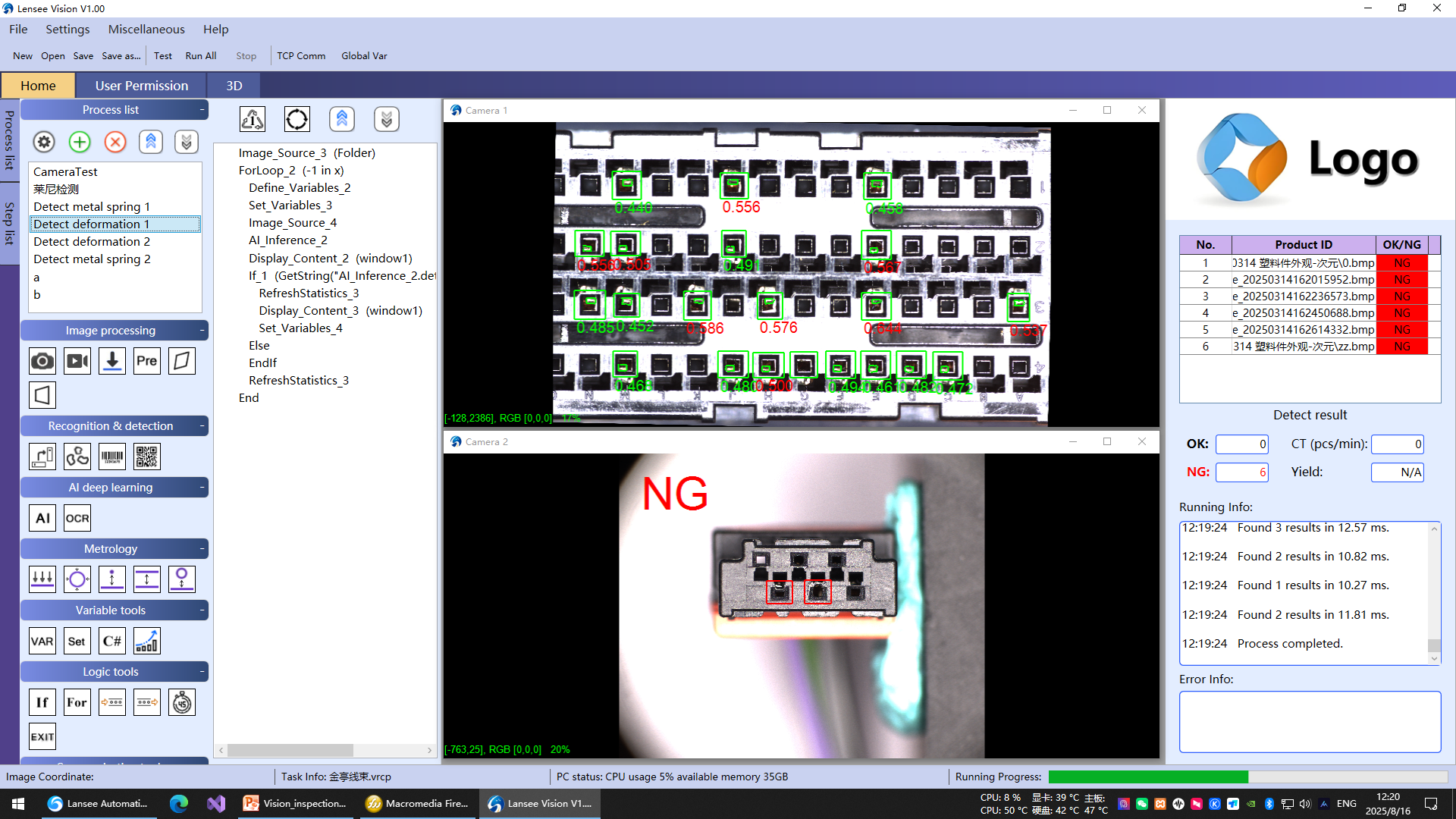

2. Our vision app: For many vision-related projects, rewriting or modifying code at the base level—using languages like C++ or C#—can be time-consuming and costly, requiring extensive programming expertise and increasing both project timelines and labor costs. To address this, we have developed a zero-code/low-code vision platform that is intuitive, easy to learn, and quick to deploy. With our app, there is little need to put highly specialized programmers to automated vision inspection projects; anyone with basic programming knowledge—or even a motivated beginner—can rapidly implement vision solutions. The platform currently offers a comprehensive suite of tools, including image acquisition, image preprocessing, AI-based prediction, OCR, template matching, and calibration. Support for simple axis motion and IO control will be available soon.

Contact Us

Contact us to obtain more information about our AI software products, vision inspection and automation solutions, and quotations for your processes.

Lensee Automation—Empowering exceptional manufacturing with customizable smart vision and automation!

WhatsApp: +1 (623) 271 5363

Tel: +86 13360854135

Email: milohwae@gmail.com